E&C Vietnam Environmental Technology Service joint-stock company specializes in providing services about wastewater treatment, consulting, and installation designing for wastewater treatment systems for the plating industry with modern technology, high efficiency, and reasonable price.

Plating wastewater characteristics

Plating is a metal machining industry to protect the surface, ensuring the aesthetics and quality of metal products.

This field has three different plating ways: electroplating, chemical plating, hot-dip plating. Besides, depending on each metal material, plating also breaks down into Chromium, zinc, nickel, or alloy plating…

According to estimates, a manufacturing factory average is discharged at 5-10 m3/day. The pollutants in wastewater can be classified into these groups:

- Heavy Metal: depending on the metal-plated, source of pollution may be Chromium, Nickel,... If they are accumulated in natural, it will threaten human health and aquatic animals, deciduous, affect to links of the food chain causing an ecological imbalance.

- Toxics: depending on the metal salt used that wastewater also contains toxic substances such as cyanide, sulfate, ammonium,...

- Substances that change the pH such as acid and alkaline: The pH value of the wastewater from the plating industry fluctuates widely (2-11). If the pH <3, waster is acidic, and if pH>9, wastewater is strongly alkaline. Both of these pollute the environment.

- Grease and other pollutants transform into suspended solids such as hydroxides, carbonates, and phosphates …

For these reasons, we need to treat the plating wastewater before discharge to the environment to protect the source of water and human health.

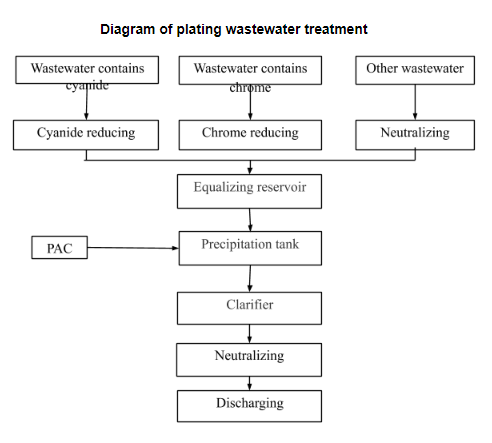

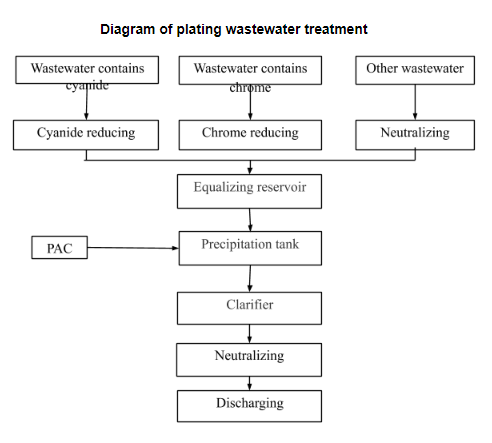

Plating wastewater treatment process.

As COD and BOD are pollution parameters that in low concentration in plating wastewater, they are not treated objects. The system concentrates on inorganic ions, especially heavy metal salts such as chromium, nickel, zinc, aluminum, iron …, and stabilizes the pH, guaranteed the discharge standard as prescribed in Vietnam.

The basic stages of the process

- Gully grates: wastewater slides through sewer grates and goes into a tank. Large size wastes are retained in this stage to avoid damaging the rear system.

- Equalizing reservoir: Being equipped air supply device to stabilize waste flow and concentration before passing through the precipitation tank.

- Reaction tank: in the tank, the pH is suitably adjusted by using chemicals such as H2SO4, FeSO4, NAOH… Besides, the tank also equipped paddle to evenly mixing of wastewater.

- Precipitation tank: This is the important stage, it helps to remove metals in the water. A chemical reaction drawer, aluminum alum is used for the flocculation reaction, and then wastewater goes through another drawer to bond the flocculant by Polymer.

- Clarifier: wastewater flows through a clarifier tank to separate sediment from wastewater, sediment is led through sludge tanks, surface wastewater flows through the intermediate tank.

- Intermediate tank: This tank is responsible for regulating the waste flow, prepare for the next treatment stage.

- Ion exchange tank: Treats the remaining metal ions in comparison to the quality meeting QCVN 40:2011/BTNMT standard - National technical regulation on industrial wastewater.

- Treated water tank: Storing water before discharging into the environment.

Notes:

- Plating wastewater flow can be separated into streams according to the nature of the source for treating: The flow contains chromium, nickel, zinc,...

- Particularly, the waste stream contains cyanide after being led through the sewer grate, clarifier, the intermediate tank will be led into the redox tank with oxidizing agents such as chlorine, NaOCl, CaOCl2 ... to oxidize cyanide in wastewater to a non-toxic compound.

It’s all the information about the plating wastewater nature and treatment method. If you want for more detail and advice please contact:

E&C Vietnam Environment Technology Services Joint Stock Company

Address: Alley 124, Phu Dien Street, Phu Dien Ward, Bac Tu Liem District, Ha Noi City

Phone: 0986.335.848 / Hotline: 0941.113.286

Website: eclim.vn

Fanpage: facebook.com/dichvucongnghemoitruong

Email: antam@eclim.vn

0 comments