Eclim specializes in the construction of wastewater treatment systems for the prestigious and professional paper industry with optimal solutions and saving operating costs for standard output quality.

The paper industry plays an important role in our country's economy. The more demand for paper increases, the more manufactures also appear. However, this industry generates wastewater which is difficult to treat, and a suitable paper industry wastewater treatment technology is needed.

The paper manufacturing process usually goes through the following main steps: Raw materials (bamboo, wood, scrap paper ...) → Machining → Bleaching → Pulping → Papermaking → Final products.

Wastewater from the paper industry contains a large amount of:

Suspensions and fibers come from pulping and papermaking processes.

Organic compounds are difficult and easily biodegradable, with BOD5/COD ≤0.55, COD content is high over 1000mg/l comes from the cooking and washing process (waste stream from cooking, washing is also called fluid black).

The detergents and organic compounds come from the bleaching process.

In fact, many wastewater treatment systems apply different technologies, includes simple equipment such as settling glue to complex ones, and the application of advanced technologies.

However, the application of technologies must be consistent with the properties of the wastewater, so that it meets the technical standards; and saving in construction, management, and operation.

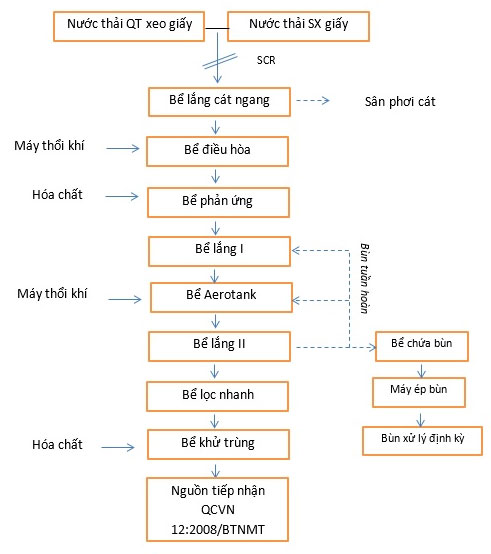

Wastewater treatment technology in the paper industry can be divided into three categories: mechanical treatment (deposition method), chemical (chemical coagulation), and biological method.

Deposition method

Using a hopper settling device to recover pulp and fiber in the pulping and papermaking process. Attention should be paid to the suitable retention time, not to anaerobic decomposition. To improve deposition efficiency and increase retention time, compressed air can be blown.

Chemical coagulation method:

Using flocculants such as iron alum, aluminum alum or lime, and polymers before or after biological treatment speed up sedimentation, glue support. The purpose of this is to treat suspensions, dissolved organic matter, phosphorus compounds, toxins, and decolorization.

Biological method:

Paper wastewater has a high content of organic matter, especially lignin compounds that are not able to decompose anaerobically or do very slowly, so it is necessary to separate lignin in black fluid before using biological methods.

Besides, the carbohydrate content of the wastewater of the pulp and paper industry is high, and need additional nutrients such as nitrogen and phosphorus, which are required for microorganism to function, decompose anaerobically and anaerobically.

Note: Choosing the appropriate wastewater treatment technology for the paper industry needs to consider the following factors:

- Has black fluid been treated or not?

- What is the circulation rate?

- What are the characteristics of the waste stream?

Wastewater treatment systems in the paper industry can be individually treated for each stream and then treated with another stream or centralized treatment with domestic wastewater.

E&C Vietnam Environmental Services Joint Stock Company - Specialist in the field of industrial wastewater treatment (Paper industry)

With extensive experience in the design of many industrial wastewater treatment systems, the Company commits to customers:

Our tips for reducing wastewater and pollutants in the waste stream of the paper industry:

If your business needs further advice on the wastewater treatment system for the paper industry, do not hesitate to contact us at hotline 0941 113 286.

0 comments