Call now 0941.113.286 to get advice on the best products from ECLIM.

Dental clinic wastewater treatment

To put a dental clinic into operation, there are many factors that must be followed, including licensing criteria from the Ministry of Health, of which building a standard dental clinic wastewater treatment system is is one of the most important factors to protect the surrounding living environment.

Nowadays, the economy is increasingly innovating and developing, and people's lives are increasingly improving. Therefore, more and more health care and beauty services for people are born. Therefore, dental clinics with a scale of 2 - 5 chairs were born to serve the needs of people more and more, especially in big cities and then in small provinces. While most large-scale hospitals have built wastewater treatment systems, small-scale dental facilities have not invested in dental wastewater treatment systems .

Eclim Vietnam - A unit specializing in constructing dental clinic wastewater treatment systems

Therefore, to ensure that the operations of clinics do not affect the environment, the Department of Health has directed that any medical facility that wants to apply for an operating license or renew its license must have a wastewater treatment system. Standard orthodontic clinic at the facility.

Wastewater from dental machines and laboratories: This wastewater contains a lot of blood, organic compounds, chemicals, disinfectants, detergents, etc. The nature of this waste stream contains many organic compounds, oil and grease, Nitrogen and phosphorus compounds and many pathogenic microorganisms

Wastewater generated from the activities of clinic staff and patients: This wastewater contains many suspended compounds, grease generated during the eating process, organic compounds and pathogenic microorganisms.

Untreated wastewater at dental clinics is mostly contaminated with microorganisms and carries dangerous pathogens, so dental wastewater needs to be thoroughly treated before being discharged into the environment to avoid affecting health. human.

MBR technology is a wastewater microbiological treatment technology using membrane filtration method. MBR stands for Membrance Bio Reactor (Membrane biological filter tank).

Medical wastewater generated from medical examination and treatment activities will be collected through a pipeline system to a collection pit. At the collection pit location, there is a submersible water pump that operates automatically via a level indicator (full water automatically pumps, low water automatically shuts off) and pumps it into the integrated wastewater treatment system using MBR technology. .

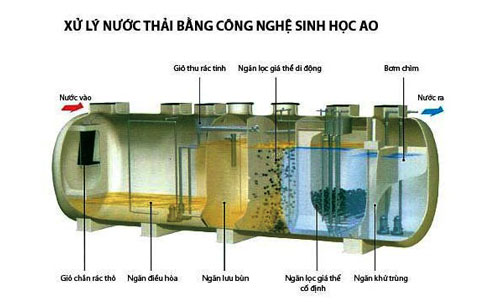

In the integrated wastewater treatment system, the following tank compartments are included:

- Wastewater conditioning compartment: Wastewater from medical examination and treatment activities is generated unevenly every day and every hour, depending on the number of patients coming for medical examination and treatment. Therefore, there must be a wastewater conditioning compartment to regulate the concentration and flow of wastewater so that it is stable before pumping it into the aerobic biological treatment compartment with an MBR membrane.

At the Wastewater Conditioning Compartment, an automatically operating pump will be arranged with an appropriate flow adjustment so that the water flow into the biological compartment is stable according to the desired treatment capacity.

- Aerobic biological treatment compartment with MBR membrane to separate clean water: In the aerobic biological treatment compartment, there are microorganisms that work to decompose organic compounds in medical wastewater. Maintain microbial activity by blowing dispersed air into the tank.

When the appropriate treatment time is reached, the clean water is separated by suction through the MBR membrane with a membrane pore size of 0.1 µm, ensuring that dirt, mud, and pathogenic microorganisms will be retained in the membrane. biological tank. Clean water will be transferred to the clean water tank. Water after being treated with microorganisms and filtered through MBR membrane meets QCVN 28:2010/BTNMT column B standards.

- Clean water tank : Clean water after treatment will be stored in the clean water tank. This compartment has the ability to store clean water to facilitate checking and using clean water after treatment to periodically backwash the membrane to ensure the membrane operates most effectively.

- Sludge compartment: For a period of time, the amount of sludge and residue in the biological tank will be large and concentrated and will be transferred to the sludge tank, from which the residue will settle, separate the water and be disposed of. However, the amount of sludge produced is not much and insignificant.

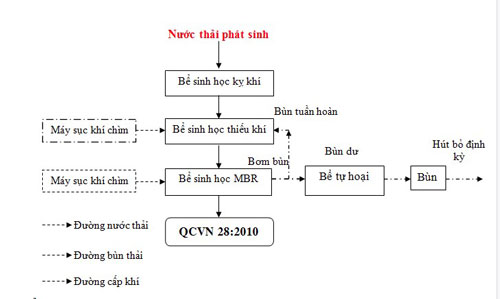

Diagram of dental clinic wastewater treatment

Advantages of MBR membrane

For large-scale dental clinics, the flow as well as the concentration of pollutants are high, therefore, if treated only through MBR technology, it is impossible to clean all the pollutants in the water. waste

For large-scale dental clinics, the treatment technology according to the above diagram can be applied. In addition to applying MBR technology, it is possible to previously use anaerobic and anoxic biological methods to treat high concentrations of organic pollutants, treat Nitrogen and Phosphorus in wastewater... The construction of two more Anaerobic and anoxic tanks take up a lot of space and investment costs, so for dental clinic wastewater treatment systems with a scale of several hundred liters, there is no need to implement the above method.

AO treatment technology is suitable for about 80% of hospitals today because this technology effectively treats both BOD , COD , Ammonium, and Nitrate. High processing efficiency with advanced processing processes has helped AO technology become superior compared to similar technologies.

Wastewater is led through the water collection system to the wastewater collection pit. Reinforced concrete wastewater collection pits were built to collect wastewater from discharge locations in the hospital. At the wastewater collection pit, there are 2 submersible pumps (operating alternately) to pump water from the collection pit to the regulation tank. The submersible pump operates according to the water level and automatically pumps wastewater to the equalization tank through the water pipeline system to the equalization tank to regulate flow and concentration.

The regulating tank functions to regulate the flow and concentration of water flow to avoid shocking the load on subsequent biological treatment systems. The conditioning tank is designed with a retention time of > 12 hours to ensure the water source is always stable in flow and concentration. The equalization tank also has a preliminary settling effect to settle all suspended sediments in wastewater to avoid affecting subsequent biological treatment processes. The equalization tank is equipped with 2 pumps to pump wastewater from the equalization tank through the anoxic biological tank (AO treatment tank cluster).

The biological treatment process lacks air to completely remove the amount of ammonium in wastewater. The anoxic biological treatment tank is implanted with appropriate strains of anoxic microorganisms to help completely remove Nitrate and partially remove COD and BOD. The anoxic biological tank is stirred with a circulating sludge pump to help push nitrogen gas (generated from the denitrification process: NO3– ® N2) out of the waste stream.

Then the water from the anoxic biological tank will be led through the aerobic biological tank. In the aerobic biological tank, aerobic microorganisms are cultured and supplied with oxygen by an aerator (combined with a fine distribution disc, providing enough dissolved oxygen for microorganisms to grow) to completely eliminate the bacteria. Set the remaining COD and BOD and convert all ammonium into Nitrate (will be reduced in the anoxic biological tank).

After the wastewater is completely decontaminated, the wastewater is separated from the aerobic microbial sludge from the wastewater stream in the sedimentation tank. The sludge in the biological sedimentation tank is pumped to the anoxic biological tank to maintain the amount of biological sludge in the tank and for the anoxic tank to remove the remaining Nitrate in the waste stream. After a period of time, the sludge in the biological tank will be discharged to a lesser extent. into the sludge compression tank. The sludge compression tank will separate water from the sludge to reduce sludge treatment costs. After being compressed, the sludge will decompose anaerobically in the tank to reduce the amount of sludge. Sludge can be pumped to the septic tank and periodically removed. After being treated with technology, clear water is sterilized with chlorine (using a metered pump and disinfection tank) to kill disease-causing bacteria and viruses, ensuring the water source does not affect the environment.

Wastewater after going through the wastewater treatment system using AO technology combined with the disinfection process will have all COD, Nitrogen, Phosphorus, and disease-causing microorganisms removed. Treated wastewater meets standards according to QCVN 28:2010/BTNMT - column A.

For large hospitals, the investment and construction of a standard wastewater treatment system has been planned since the project was established, while small hospitals or clinics do not have such conditions because they have to hire site, must renovate or build a new site but there is not enough financial resources to build a wastewater treatment system from the beginning. E&C Vietnam Environmental Technology Services Joint Stock Company is a unit specializing in designing and constructing small-scale wastewater treatment systems with a capacity of 500 liters/day ==> 20m3/day and night suitable for small clinics and hospitals.

The dental clinic wastewater treatment system is designed by E&C Vietnam environmental technology company in a modular form, making it very convenient for relocating equipment or if the clinic needs to expand capacity, the system It is completely possible to install new modules to suit the actual needs of customers.

Customers who need advice & installation of a wastewater treatment system at the Dental - Maxillofacial Clinic - Please contact:

E&c VIETNAM ENVIRONMENTAL TECHNOLOGY JOINT STOCK COMPANY

Website: eclim.vn

☎ Hotline: 0941 113 286 - 0968 279 976

Address: Head office No. 383 Pham Van Dong, Xuan Dinh, Bac Tu Liem, Hanoi.

0 comments