Eclim provides pig farming wastewater treatment system hotline 0941.113.286

Surely everyone knows the danger of wastewater in pig farming. Therefore, if the amount of water discharged into the environment is not treated early, it will directly affect the lives and health of humans and animals. Currently, there are many methods of treating pig wastewater such as manure, biogas technology, physical chemistry, biological ponds... to control odors and reduce the amount of pollutants in wastewater before treatment. discharged to the outside.

Pig farming wastewater has a high content of organic substances and nutrients expressed through parameters such as: COD, BOD5, SS... In addition, pig farming wastewater contains high levels of N and P. Besides, it also contains large amounts of bacteria that cause extremely dangerous diseases that affect the health of humans as well as other animals in the area.

In pig farms, a simple, time-saving way to clean manure is to use water to wash. The final wastewater contains 70-80% organic matter including carbon hydrates, amino acids, proteins, fats, cellulose and their derivatives found in feces and food scraps. Besides, there are easily decomposed organic substances, inorganic substances account for 20-30% including soil, sand, salts, urea, chloride, SO42-...

Washing the barn with water also makes it difficult to collect dry manure. Besides some farming households that often use dry manure to fertilize their fields, most do not collect manure. Therefore, on most farms, manure and wastewater must be collected together for treatment. Feces contain a very small portion of garbage, fillers and leftover food. In the process of treating farm wastewater, both wastewater and feces must be treated simultaneously.

The World Health Organization (WHO) has warned that if there are no adequate measures to collect and treat pig farming waste, it will seriously affect human and animal health and cause serious environmental pollution. important. Pig farming wastewater contains dangerous levels of pollutants, many pathogens, bacteria and viruses that cause disease. It not only affects the environment, polluting the country's air, but also affects human health. The main cause of many respiratory and digestive diseases such as diarrhea, cholera... is because the waste contains many disease-causing microorganisms, worm eggs, etc. Especially viruses that mutate from diseases such as foot-and-mouth disease, foot-and-mouth disease, and blue-ear disease can spread quickly and can be dangerous to human life.

Wastewater causes pollution, directly affecting human health

Pig farming wastewater from livestock households is also causing problems and affecting the living space of other surrounding households. Therefore, treating pig farming wastewater to reduce odors, bacteria and pathogens is an extremely necessary issue for organizations, businesses, individuals and households raising pigs. Pig farming wastewater has a very unpleasant odor, color, and moss clinging to the lake. If pig farming wastewater is not treated promptly before being discharged into rivers, ponds, and lakes, it will pollute the environment, generate toxic gases, and chemical reactions of organic substances in the water will dry out the water. Gradually depleting the amount of dissolved oxygen in water, causing eutrophication due to excess N and P, killing many other organisms in the water, affecting plants and creating favorable conditions for harmful bacteria to grow. develop.

Use trash screens and preliminary sedimentation tanks to remove large solids from water. The purpose of this method is to separate solids, residue, and feces from the wastewater mixture by collecting and separating them. Alternatively, centrifugation or filtration methods can be applied. The suspended sediment content in livestock wastewater is quite large and settleable, so it can be preliminarily sedimented before moving on to the next treatment stages. The remaining solids are composted to make fertilizer.

Conventional mechanical treatment methods take a lot of time and are not very effective because livestock wastewater contains many organic substances, inorganic substances are small in size, cannot settle, and some are microorganisms. Objects are small in size, so it is necessary to apply flocculation method to remove them. Use coagulants such as aluminum alum, iron alum, mud alum,... combined with flocculation aid polymer to increase the flocculation process.

Principle: flocculant particles (usually aluminum hydroxide and iron hydroxide particles) have opposite charges to the suspended substances in wastewater (usually negative charges). During the moving process, these oppositely charged particles will coalesce into larger flocs and easily settle into the water, making the filtration process more effective.

Based on the ability of microorganisms to decompose organic substances in aerobic or anaerobic environments. They use organic matter and some minerals as food and to produce energy. When decomposed, it will reduce the organic matter content in the water and will make the water cleaner. Depending on whether the microorganisms are aerobic, anaerobic or anaerobic, wastewater treatment works should be designed accordingly. This method is often used in biological treatment tanks such as Aerotank tanks, UASB tanks...

- Aerobic treatment method : Using a group of aerobic microorganisms, operating in the presence of oxygen.

- Anaerobic treatment method : Using microorganisms to decompose organic matter in environmental conditions with little or no oxygen. This process goes through 4 stages:

- Hydrolysis : Under the effect of enzymes secreted by bacteria, it helps decompose complex insoluble organic substances into simple substances that are soluble in water (amino acids, fatty acids, sugars...)

First, wastewater will flow into the biogas tank to treat large amounts of organic matter, reduce toxic gases, kill pathogens and can provide gas to help save costs. Next, the wastewater flows into the equalization tank and is stirred to evenly mix the concentration and flow.

Wastewater continues from the equalization tank through the UASB tank thanks to anaerobic microorganisms decomposing organic matter. The decomposition process creates methane CH4 and carbon dioxide CO2 bubbles that float to the top and are captured by air hoods to lead out of the tank. The wastewater treatment process at the UASB tank only reduces the amount of BOD but the wastewater does not meet allowed standards. It is necessary to use an additional AEROTANK tank for more thorough treatment.

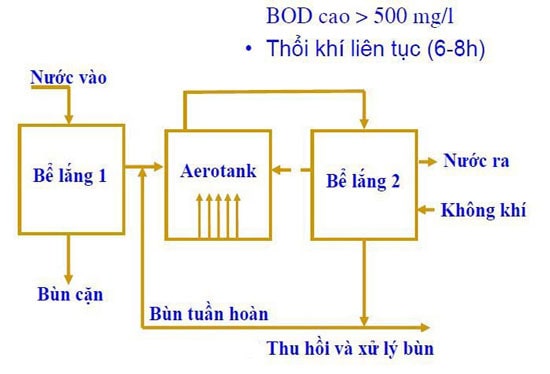

Figure: Aerotank biological treatment technology diagram

Principle: Water is introduced from the top of the tank, aeration at the bottom of the tank helps microorganisms and organic matter mix and provides oxygen for microorganisms. In the tank, aerobic organisms decompose organic matter according to the reaction equation:

CHC + O2 -> CO2 + H2O + NO3- + SO42- + heat + biological cells.

Wastewater is sent to settling tank 2 to remove activated sludge flocs. Part of the sludge is circulated in the Aerotank tank to maintain microbial density in the tank.

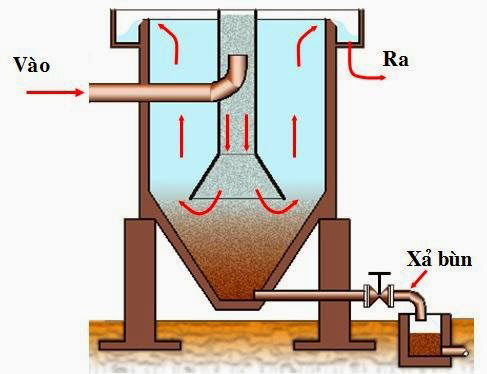

After aerobic biological treatment, the wastewater is passed through the second stage sedimentation tank (Vertical settling tank) to separate and settle the excess biomass formed during the aerobic biological treatment process in the Aerotank tank. Principle: Taking advantage of gravity, biomass flocs that are insoluble in water will settle to the bottom and be discharged through the sludge discharge line.

Vertical settling tank

Finally, there is the sterilization stage at the sterilization tank. Liquid chlorine is often used to remove bacteria and oxidize organic substances. Liquid chlorine is cheap and easy to transport, so it is commonly used. You can also use Javen water.

Finally, the wastewater is discharged into the receiving source according to QCVN 62-MT:2016/BTNMT on livestock wastewater.

0 comments