Eclim consults and designs livestock and poultry wastewater treatment systems hotline 0941.113.286

Cattle slaughter wastewater has a high content of organic substances and nutrients expressed through parameters such as: COD, BOD5, SS... In addition, pig farming wastewater contains high levels of N and P. . Besides, it also contains large amounts of bacteria that cause extremely dangerous diseases that affect the health of humans as well as other animals in the area.

In pig farms, a simple, time-saving way to clean manure is to use water to wash. The final wastewater contains 70-80% organic matter, including carbon hydrates, amino acids, proteins, fats and their derivatives found in feces and food scraps. Besides, there are easily decomposed organic substances, inorganic substances account for 20-30% including soil, sand, salts, urea, chloride, SO42-...

|

Parameter |

Unit |

Livestock slaughter wastewater |

|

pH |

- |

6.5-10 |

|

Volume of wastewater |

m3/ton of slaughtered cattle meat |

3-8 |

|

BOD7 |

mg/l |

2000 |

|

Total Nitrogen |

mg/l |

100-200 |

|

Total Phosphorus |

mg/l |

10-20 |

|

total suspended solids |

mg/l |

100-500 |

|

Fat |

mg/l |

50-150 |

Source of wastewater from livestock slaughtering

Solid waste

Solid waste is mainly from cattle hair, blood, and pig feces. During the slaughtering process, solid waste is hardly collected, it is discharged into sewers, rivers and lakes when workers wash barns. This is the cause of clogged pipes, increasing the amount of water discharged into the environment. A part of livestock manure is composted by people as fertilizer. If not used, it will be discharged directly into the environment, causing environmental pollution and spreading dangerous pathogens.

Wastewater

- Pig farming wastewater has a high content of organic substances and nutrients expressed through parameters such as: COD, BOD5, SS... In addition, pig farming wastewater contains high levels of N and P. . Besides, it also contains large amounts of bacteria that cause extremely dangerous diseases that affect the health of humans as well as other animals in the area.

In pig farms, a simple, time-saving way to clean manure is to use water to wash. The final wastewater contains 70-80% organic matter including carbon hydrates, amino acids, proteins, fats, cellulose and their derivatives found in feces and food scraps. Besides, there are easily decomposed organic substances, inorganic substances account for 20-30% including soil, sand, salts, urea, chloride, SO42-...

Currently, the problem of environmental pollution due to wastewater from livestock slaughterhouses is in an alarming state. Wastewater and solid waste are not treated but discharged directly into the environment, polluting the surrounding environment and affecting human health. In particular, wastewater contains many parasites and worms, causing many dangerous diseases. In the process of slaughtering cattle, the entrails stage is a step that generates polluted wastewater. In slaughterhouses that process skin, there is often brine mixed with blood poured into the wastewater system.

Wastewater from slaughterhouses will pass through the trash screen to remove large-sized trash such as hair, skin, bones, etc. Then the wastewater is sent through the oil and grease separator, while the remaining solids will be removed. is deposited to the bottom and sent to the next stage. Next, the water will flow through the pipe into the conditioning tank, with the aim of evenly mixing the concentration and flow, helping to stabilize the water flow, adjust the pH...

Wastewater continues from the equalization tank through the UASB tank thanks to anaerobic microorganisms decomposing organic matter. The decomposition process creates methane CH4 and carbon dioxide CO2 bubbles that float to the top and are captured by air hoods to lead out of the tank. The wastewater treatment process at the UASB tank only reduces the amount of BOD but the wastewater does not meet allowed standards. It is necessary to use an additional AEROTANK tank for more thorough treatment.

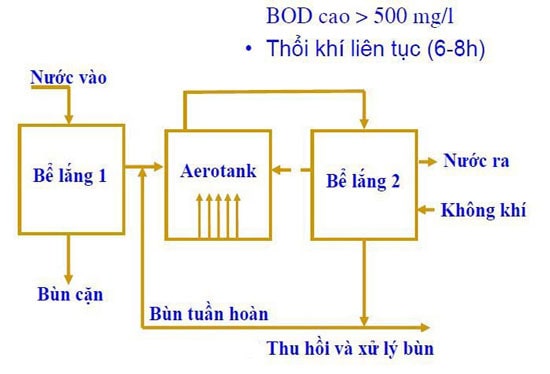

Aerotank aerobic biological treatment technology.

Illustration: Aerotank biological treatment technology diagram

Principle: Water is introduced from the top of the tank, aeration at the bottom of the tank helps microorganisms and organic matter mix and provides oxygen for microorganisms. In the tank, aerobic organisms decompose organic matter according to the reaction equation:

CHC + O2 → CO2 + H2O + NO3- + SO42- + heat + biological cells.

Wastewater is sent to settling tank 2 to remove activated sludge flocs. Part of the sludge is circulated in the Aerotank tank to maintain microbial density in the tank.

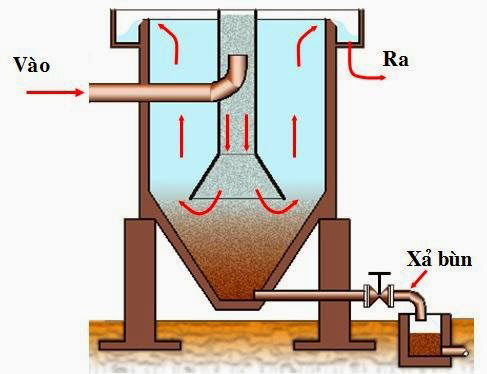

After aerobic biological treatment, the wastewater is passed through the second stage sedimentation tank (Vertical settling tank) to separate and settle the excess biomass formed during the aerobic biological treatment process in the Aerotank tank. Principle: Taking advantage of gravity, biomass flocs that are insoluble in water will settle to the bottom and be discharged through the sludge discharge line.

Vertical settling tank

Finally, there is the sterilization stage at the sterilization tank. Liquid chlorine is often used to remove bacteria and oxidize organic substances. Liquid chlorine is cheap and easy to transport, so it is commonly used. You can also use Javen water.

Finally, the wastewater is discharged into the receiving source, ensuring compliance with QCVN 40:2011/BTNMT standards.

0 comments