Eclim consults and designs livestock and poultry wastewater treatment systems hotline 0941.113.286

Wastewater characteristics and pollution parameters

Wastewater at poultry farms and slaughterhouses has extremely complex composition, including wastewater from washing barns and slaughterhouses, domestic wastewater from workers, and wastewater from cleaning tools. slaughtering... Wastewater contains a large amount of oil and grease, high levels of organic substances, including elements N, P and preservatives for food, hair, bones of animals...

Ingredient:

+ Organic matter: accounts for 70-80% including amino acids, fats, proxides, hydrocarbon compounds and their derivatives in feces and leftovers.

+ Inorganic substances account for 20-30% including soil, sand, chloride salt, SO42-...

+ Nitrogen and phosphorus: animals absorb N and P very poorly, so they only absorb 30% of N to form products for the body, the remaining 70% is excreted. Over time, N in water will be oxidized into different substances such as NO3-, NH4+, NO2-... During the process of consuming animal food, P is also created (accounting for 0.25-1.4%). The amount of P in water accounts for a high proportion, existing in different forms such as HPO42-, H2PO4, PO43-... and organic phosphates.

+ Microorganisms: contains many bacteria and viruses that cause dangerous diseases. It also contains large amounts of helminth eggs, which are the cause of dangerous diseases for humans and pets.

Impact on the environment

Slaughter wastewater contains many organic substances and very high nitrogen content, contaminated by blood, fat, phosphorus, nitrogen and detergents and preservatives. Solid waste generated from the operations of slaughterhouses includes: poultry carcasses, feathers, substances in poultry gizzards, feces and other organic components. During the slaughtering process, waste is hardly collected, it is discharged into sewers or ponds with wastewater when workers wash barns. This action not only causes pipeline blockage but also generates a large amount of waste into the environment.

Noise pollution problem: From means of transportation, used machinery and equipment such as ventilators, air compressors,... or the noise of poultry, chickens and ducks...

Our country has an intricate and dense river system spreading across the length of the country. This is a source of surface water that is extremely important in socio-economic development. River and lake water pollution is an issue of deep concern. The phenomenon of excess nutrients (nitrogen, phosphorus) stimulates the growth of algae and phototrophic organisms, leading to eutrophication, depleting oxygen, causing death of river organisms in the water and negatively affecting the environment. ecological environment.

► Effects on human health : People exploit river and lake water to serve daily activities as well as agricultural irrigation. However, river and lake water smells bad, is pitch black, and waste and poultry feathers are everywhere. Not only does it lose water supply, but it also causes disease if people use it. A series of gastrointestinal diseases such as cholera, dysentery, diarrhea... then diseases of the hands, feet, mouth, skin diseases and especially a very high risk of cancer. If water is not treated promptly, it will be a huge threat affecting the ecosystem, livelihoods and human health.

Wastewater from slaughterhouses will pass through the trash screen to remove large-sized trash such as hair, skin, bones, etc. Then the wastewater is sent through the oil and grease separator, while the remaining solids will be removed. is deposited to the bottom and sent to the next stage. Next, the water will flow through the pipe into the conditioning tank, with the aim of evenly mixing the concentration and flow, helping to stabilize the water flow, adjust the pH...

Wastewater continues from the equalization tank through the UASB tank thanks to anaerobic microorganisms decomposing organic matter. The decomposition process creates methane CH4 and carbon dioxide CO2 bubbles that float to the top and are captured by air hoods to lead out of the tank. The wastewater treatment process at the UASB tank only reduces the amount of BOD but the wastewater does not meet allowed standards. It is necessary to use an additional AEROTANK tank for more thorough treatment.

Aerotank aerobic biological treatment technology

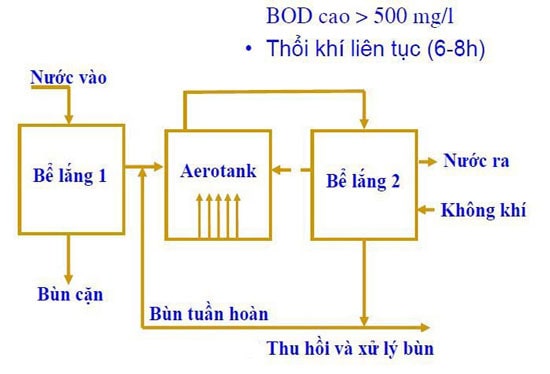

Illustration: Aerotank biological treatment technology diagram

Principle : Water is introduced from the top of the tank, aeration at the bottom of the tank helps microorganisms and organic matter mix and provides oxygen for microorganisms. In the tank, aerobic organisms decompose organic matter according to the reaction equation:

CHC + O2 → CO2 + H2O + NO3- + SO42- + heat + biological cells.

Wastewater is sent to settling tank 2 to remove activated sludge flocs. Part of the sludge is circulated in the Aerotank tank to maintain microbial density in the tank.

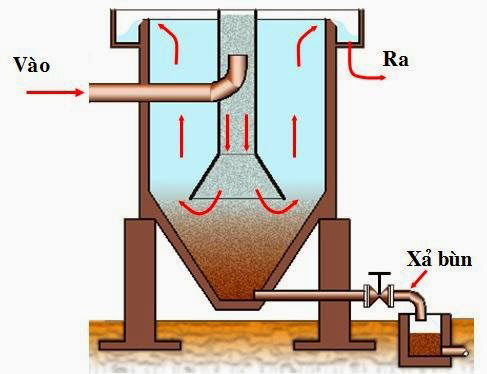

After aerobic biological treatment, the wastewater is passed through the second stage sedimentation tank (Vertical settling tank) to separate and settle the excess biomass formed during the aerobic biological treatment process in the Aerotank tank. Principle: Taking advantage of gravity, biomass flocs that are insoluble in water will settle to the bottom and be discharged through the sludge discharge line.

Finally, there is the sterilization stage at the sterilization tank. Liquid chlorine is often used to remove bacteria and oxidize organic substances. Liquid chlorine is cheap and easy to transport, so it is commonly used. You can also use Javen water.

Finally, the wastewater is discharged into the receiving source, ensuring compliance with QCVN 40:2011/BTNMT standards.

Customers who need advice and installation of wastewater treatment technology for poultry and chicken slaughterhouses, please contact:

ECLIM VIETNAM ENVIRONMENT JOINT STOCK COMPANY

Website: http://eclim.vn

☎ Hotline: 0941 113 286 - 0968 279 976

Address: 383 Pham Van Dong, Xuan Dinh, Bac Tu Liem, Hanoi

0 comments