Specializing in consulting and installing wastewater treatment systems for metallurgical plants and heavy industries using the latest technology, ensuring clean water to the outside environment.

Metallurgical industry wastewater contains heavy metals such as chromium, lead, copper, iron, nickel, zinc... which can accumulate in living animals, indirectly causing many problems for human health. such as stomach diseases, respiratory diseases and cancer.

Each metal or alloy that needs to be produced has its own method, so the wastewater of each metallurgical plant will be different in both quality and quantity. Wastewater treatment technology in the metallurgical industry also has differences, however, they all have some basic things in common as below.

The amount of wastewater from metallurgical plants is very large, including: :

Wastewater treatment technology containing metals includes:

In the case of metallurgy containing heavy metals, the most common technology is chemical technology applying chemical precipitation method, combined with coagulation.

Precipitation method: Use chemicals such as milk of lime, soda and caustic soda to adjust the pH to a weak alkaline or alkaline value, so that the metal precipitates.

Flocculation method: Flocculation chemicals such as aluminum alum and iron alum are added to promote the formation of floc. In addition, there is also an anionic polymer glue aid and a slow-speed agitator system, so that the flocs move, collide and stick together to form large flocs that settle to the bottom.

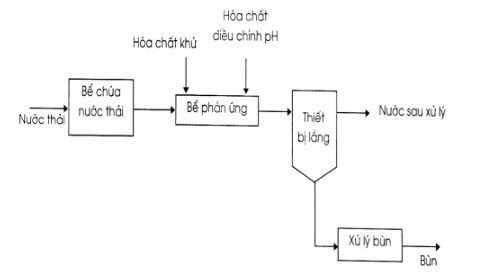

Diagram of wastewater treatment system for basic metallurgy industry

Wastewater from metallurgy and metal processing industries contains high levels of heavy metals, which need to be treated at the source to recover metals, before being sent to a centralized wastewater treatment plant. In addition, the waste stream also contains toxic substances such as cyanide, fluoride, phenol, and sulfite, so it is necessary to separate treatment channels.

Below is a diagram of the basic metallurgical industry wastewater treatment system:

The company specializes in consulting and installing the best water treatment systems

With many years of experience in industrial wastewater treatment, ECLIM - Vietnam E&C Environmental Services Joint Stock Company is ready to help your business consult, test and evaluate effective metallurgical wastewater treatment systems. with commitment:

We look forward to having the opportunity to work with you, contact us via hotline 0941 113 286

0 comments