The process of treating wastewater in the confectionery and food processing industries by anaerobic methods occurs when there is a reaction between organic matter and microorganisms to create CH4.

Food processing industry wastewater is the most difficult form of wastewater to treat. Food industry wastewater includes many different components such as nitrogen, phosphorus, animal fat, vegetable oil, and starch that have not been treated for a long time, causing stagnation and clumping...

Confectionery industry wastewater contains high levels of organic matter, detergents, grease, and excess margarine.

.

Waste when put into water will cause a decrease in oxygen in the water, causing negative impacts on organisms living in the water. Causes water sources to be seriously polluted. More seriously, if people use that water source, it can cause skin allergies, ulcers, and even long-term use can lead to cancer and death.

So wastewater treatment in the food industry is very important, what is the technology for wastewater treatment in the confectionery and food processing industries? What is the processing process? Please refer to the article below

Wastewater treatment system for food processing and confectionery industry

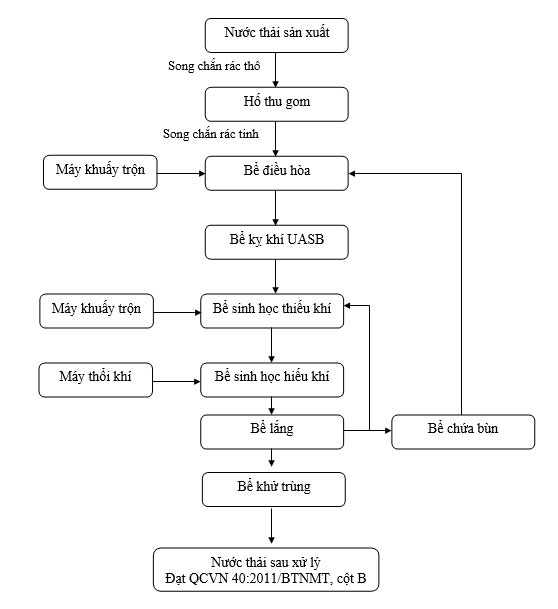

With many years of experience in the field of providing wastewater treatment services, consulting and designing and constructing wastewater treatment systems, E&C Vietnam Environmental Technology Joint Stock Company offers wastewater treatment solutions. The food processing industry in general and the confectionery industry in particular follow biotechnology as follows:

Industrial wastewater treatment diagram

1. Grease collection and separation tank

Because food processing industry wastewater contains many components, the wastewater is first put into a collection tank to separate oil and grease. Here, the waste is kept to avoid clogging the pipes, the grease scum floats to the top and is transferred to the grease tank, the wastewater will move to the next compartment.

2. Collection pit

Once the wastewater is separated, it will go to the collection pit, but before entering the collection pit, the wastewater will pass through the trash screen to remove large-sized trash to avoid clogging during operation.

3. Air conditioning tank

The regulation tank helps regulate the properties of wastewater and stabilize the flow rate. Air conditioning tanks usually have large capacities, because the larger the capacity, the higher the safety and efficiency

4. Anaerobic tank

The process of treating wastewater in the confectionery and food processing industries by anaerobic methods occurs when there is a reaction between organic matter and microorganisms to create CH4.

This decomposition process goes through 4 steps

Step 1: Hydrolysis, separating macromolecular compounds into smaller, more easily decomposed molecules

Step 2: Acidify small molecules into acetic acid, H2 and CO2

Step 3: Acetation converts the products in step 2 into new products

Step 4: Methane the products of step 3 into new products. This is also the final step in the anaerobic digestion process

5. Anoxic tank

Wastewater after being treated in the anaerobic tank will be directed to the Anoxic tank. Here, NH3 gas after a process will produce N2, pumped to the sedimentation tank, then transferred to the Aerotank.

6. Aerotank

Here, air is always supplied, microorganisms are periodically added to decompose organic matter into CO2 and H2O, reducing the concentration of dirty water in wastewater.

7. Sedimentation tank II

After being treated in the biological tank, the water will be sent to the sedimentation tank to settle the sludge in the wastewater. Part of the settled sludge is pumped to the sludge tank, part is sent to the Anoxic tank

8. Disinfection tank

Here, the bacteria are destroyed by a strong oxidant, and finally the wastewater is pumped into a pressure filter tank to remove remaining dirt, ensuring clear water is taken out.

Removes components that cause water pollution

High efficiency

New purchase and maintenance costs are low

Wastewater through the treatment process meets allowed standards

Long lifespan

Different capacities suit many different needs

Do not pollute the environment

The equipment in the system is compact, not bulky, and easy to transport

E&C Vietnam Environmental Technology Services Joint Stock Company is proud to be a leader in the field of providing wastewater treatment technology systems for the confectionery and food processing industries. For further details, please contact hotline 0941 113 286 for further advice

0 comments