The choice of methods and technology for wastewater treatment in the textile and dyeing industry depends on many factors such as funding, land, flow and wastewater characteristics of each production facility. E&C Vietnam Environmental Technology Services Joint Stock Company is a reputable industrial wastewater treatment unit, and will advise and help customers choose appropriate wastewater treatment technology.

Characteristics and environmental effects from textile and dyeing industry wastewater

The textile and dyeing industry is one of Vietnam's strengths and a key industry. However, in the production process, many fuel sources, dyes and chemicals with high levels of pollution to the environment are used.

Wastewater sources of the textile industry arise from many production stages: Sizing, rinsing, cooking, bleaching, dyeing and finishing.

Harmful effects of textile dyeing industry wastewater on the environment:

- High alkalinity increases water pH, is toxic to aquatic species, and corrodes water works.

- BOD and COD of water sources also harm aquatic life, reducing the amount of dissolved oxygen in the water.

- Large amounts of dye increase the color of the receiving water source, negatively affect the environment, increase the accumulation of toxins in the body, and create cancer risks for humans and animals.

Textile wastewater treatment methods

For the textile and dyeing industry, wastewater flow and concentration of pollutants vary greatly depending on the season; according to production items and product quality; depending on each production facility as well as changing daily. Therefore, it is necessary to survey, research, and take samples to analyze wastewater from each facility at different times; to be able to apply appropriate wastewater treatment systems and technologies for the textile and dyeing industry.

Possible treatment methods include:

- Neutralization and pH adjustment method: Mix alkaline wastewater with acidic waste stream to adjust pH to the appropriate value.

- Coagulation and flocculation method: Use aluminum alum, iron alum along with milk of lime (iron sulfate, aluminum sulfate) and calcium hydroxide to remove color and part of COD.

- Adsorption method: The adsorbent is activated carbon, charcoal or clay... used to treat substances that are not or are difficult to biodegrade.

- Oxidation method: Use strong oxidants to decolorize dyes in wastewater.

- Membrane technology: Membrane technologies such as microfiltration and ultrafiltration membranes... have the effect of recovering chemicals including PVA starch, indigo dye, salt and other dyes.

- Biological method: Because textile wastewater often lacks nitrogen and phosphorus content, it can be mixed with domestic wastewater for biological treatment with activated sludge, biological filter or oxidation lake. In addition, it is also necessary to apply local treatment methods to remove toxic substances and reduce the rate of persistent substances in wastewater before biological treatment.

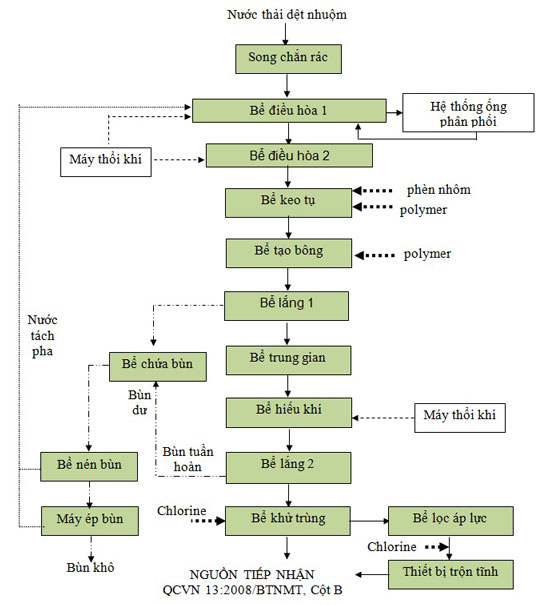

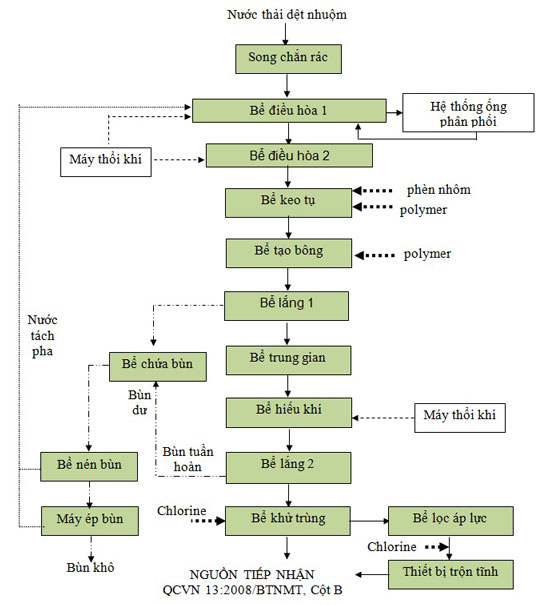

Simulation diagram of textile industry wastewater treatment technology

Modern textile and dyeing industry wastewater treatment technology using MBBR

Wastewater treatment technologies that are currently commonly applied include Aerotank (aerobic biological tank), air blowing, activated sludge, SBR and MBBR.

MBBR (Moving Bed Biofilm Reactor) is a modern technology combining traditional Aerotank and aerobic biological filtration, with outstanding advantages compared to other wastewater treatment technologies, especially traditional technology:

- High treatment efficiency: MBBR mobile media technology allows increasing microbial density many times, promoting biochemical oxidation, COD, BOD and NH4 reduction process 10 times faster than with traditional methods.

- Energy saving: MBBR technology does not require aerobic sludge circulation, aerobic microbial activity is still maintained, ensuring treatment efficiency.

- Save space: There is no need to build an anoxic anoxic tank to remove N and P like the traditional method, a reduction of 30-40% compared to suspended activated sludge technology.

- Other advantages: Simple operation and upgrade.

Please contact E&C Vietnam Environmental Technology Services Joint Stock Company if you want more advice on wastewater treatment technology for the textile and dyeing industry. Hotline 0914 113 286

0 comments