Consulting and design and construction of wastewater treatment systems for the Plating industry with modern technology, high efficiency and reasonable prices

[Plating wastewater treatment system] - E&C Vietnam Environmental Technology Joint Stock Company specializes in providing wastewater treatment services, consulting and design and construction of wastewater treatment systems for the Plating technology industry. Modern, highly efficient with reasonable price.

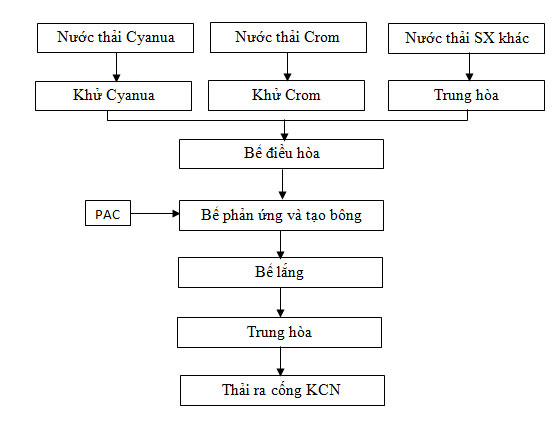

Illustration: wastewater treatment system

Plating is the metal painting and plating industry, aimed at protecting the surface, ensuring aesthetics and quality for metal products.

The plating industry applies three different forms of plating: Electroplating, chemical plating, and hot-dip plating. In addition, based on each metal material to be plated, the plating industry is also divided into Chromium plating, Zinc plating, Nickel plating, alloy plating...

According to estimates, on average a plating production facility releases 5 - 100 m3/day. Pollutants in plating wastewater can be divided into the following groups:

- Heavy metals: Based on the plated metal, the source of pollution can be Chromium, Nickel... long-term accumulation in the natural environment will threaten human health and aquatic animals. plankton, affecting the food chain in the food chain, causing ecological imbalance.

- Toxins: Depending on the type of metal salt used, wastewater also contains toxins such as cyanide, sulfate, ammonium...

- Pollutants that change the pH value such as acid and alkaline: The pH value of plating industry wastewater ranges very widely, can be from 2 to 11. If pH <3, the wastewater is acidic and if pH> 9, the wastewater is very alkaline, both types of wastewater pollute the environment.

- Oil, grease and pollutants form suspended residues such as hydroxide, carbonate and phosphate...

For the above reasons, we need to treat wastewater from the plating industry before discharging it into the outside environment, in order to protect the water source from being polluted, causing a direct impact on human health.

Because the concentration of organic substances COD and BOD of plating industry wastewater is low, it is not subject to treatment; Plating industry wastewater treatment technology mainly focuses on treating inorganic ions, especially heavy metal salts such as chromium, nickel, zinc, aluminum, iron... and stabilizing the pH value before being treated. discharged into the environment, ensuring discharge standards according to regulations in Vietnam.

Diagram of plating wastewater treatment

Garbage screen: Wastewater passes through the trash screen into the receiving tunnel. The trash screen is responsible for retaining large solid waste, avoiding affecting the wastewater treatment system behind.

Air conditioning tank: The air conditioning tank is equipped with an air supply device to stabilize the flow and concentration of waste before passing it through the reaction tank.

Reaction tank: In the reaction tank, wastewater is measured and adjusted to the appropriate pH by adding chemicals such as H2SO4, FeSO4, NAOH... In addition, the tank is also equipped with a quick stirrer to ensure even mixing of water. waste.

Coagulation - flocculation tank: This is an important step in the treatment system, effective in removing metal ions in wastewater. In the reaction compartment, alum chemical is used for the flocculation reaction, then the wastewater flows to the flocculation compartment and Polymer is added to bind the precipitates formed.

Sedimentation tank: After the flocculation process, the wastewater flows through the sedimentation tank to separate the sediment from the wastewater, the sediment is led through the sludge tank, the surface wastewater flows through the intermediate tank.

Intermediate tank: Intermediate tank to regulate wastewater flow, preparing for downstream treatment.

Ion exchange tank: Wastewater from the intermediate tank is pumped through the ion exchange tank, to treat the remaining metal ions in the wastewater, ensuring the output water quality meets QCVN 40:2011/BTNMT - Regulations. National technical standards for industrial wastewater.

Post-treated water tank: Wastewater is brought to the post-treated water tank before being discharged into the environment.

Note:

Wastewater streams in the plating industry can be separated into separate waste streams according to the nature of the waste source for treatment: Waste streams containing chromium, waste streams containing nickel, waste streams containing Zn...

Particularly, the waste stream containing cyanide, after being led through the trash screen, sedimentation tank, and equalization tank, will be led into a redox tank with oxidants such as Chlorine, NaOcl, CaOCl2... to oxidize the cyanide in the wastewater into non-toxic compound.

Above is information about the properties and treatment of wastewater from the plating industry. Customers who want to learn or need further advice on related issues please contact us

E&C Vietnam Environmental Technology Services Joint Stock Company

Address: Head office No. 14, Lane 2/33/3 Van Tri, Minh Khai, Hai Ba Trung, Hanoi

Phone: 0986.335.848 / Hotline: 0941.113.286

Website: eclim.vn

Fanpage: facebook.com/dichvucongnghemoitruong

Email: antam@eclim.vn

0 comments